All advantages top of tank

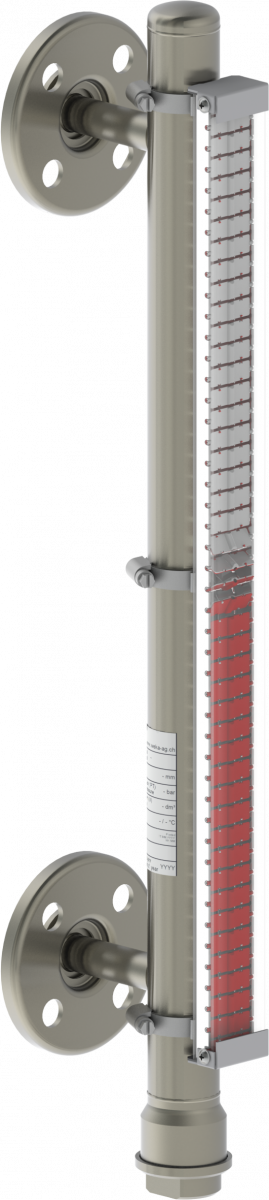

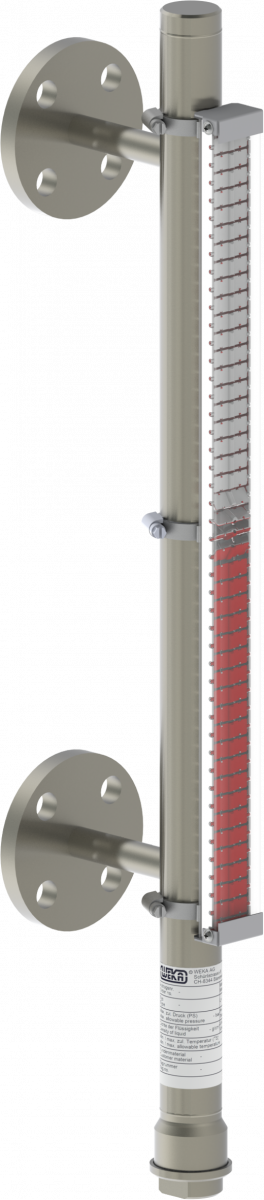

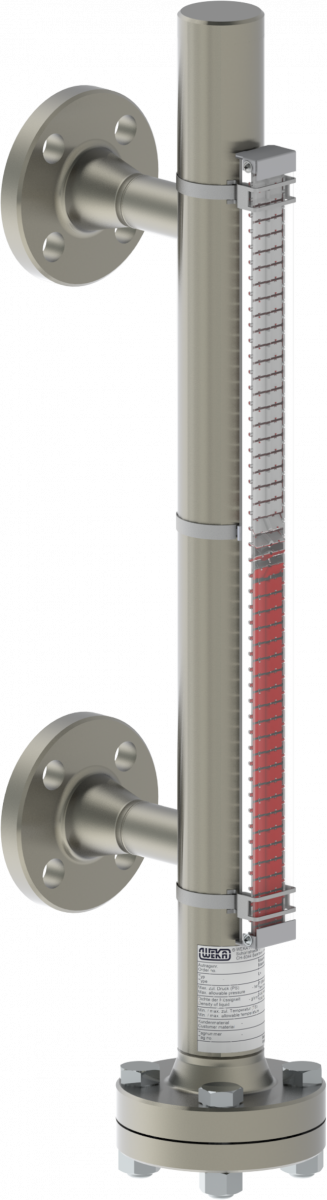

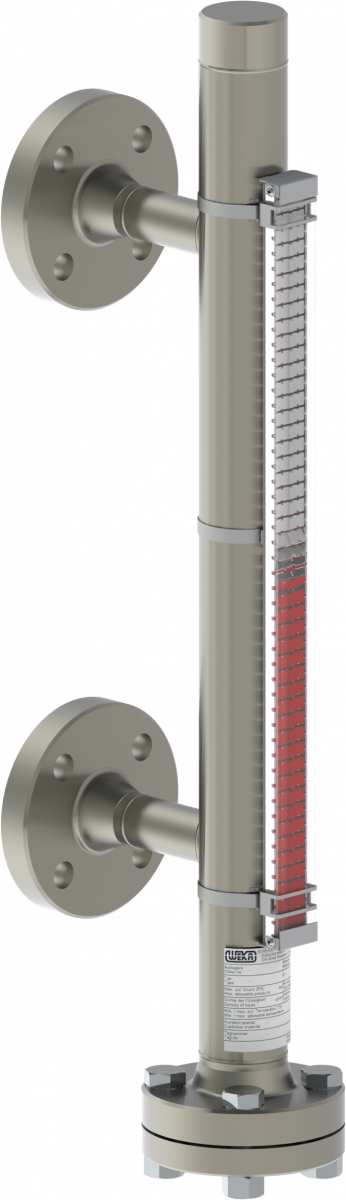

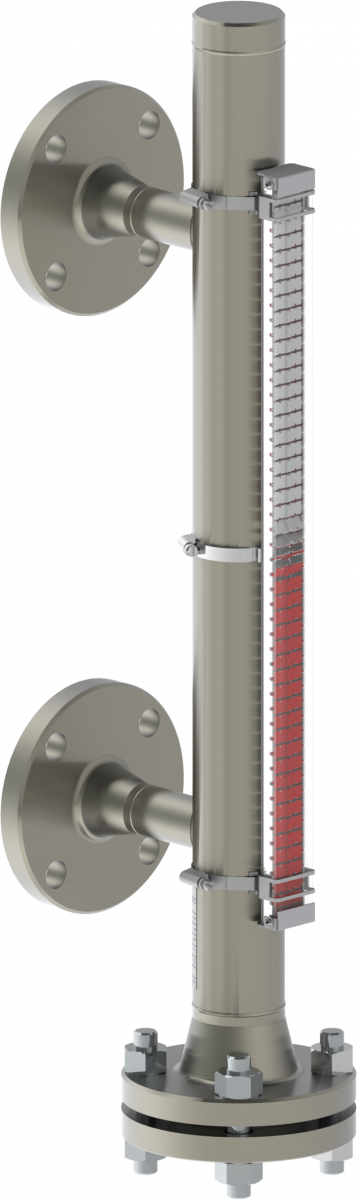

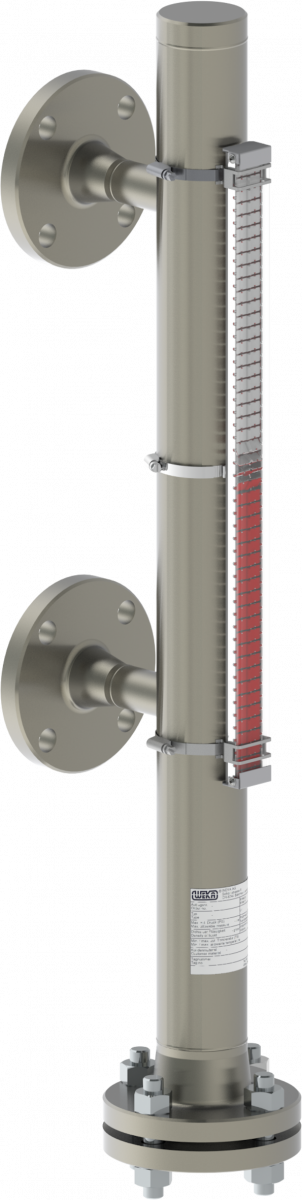

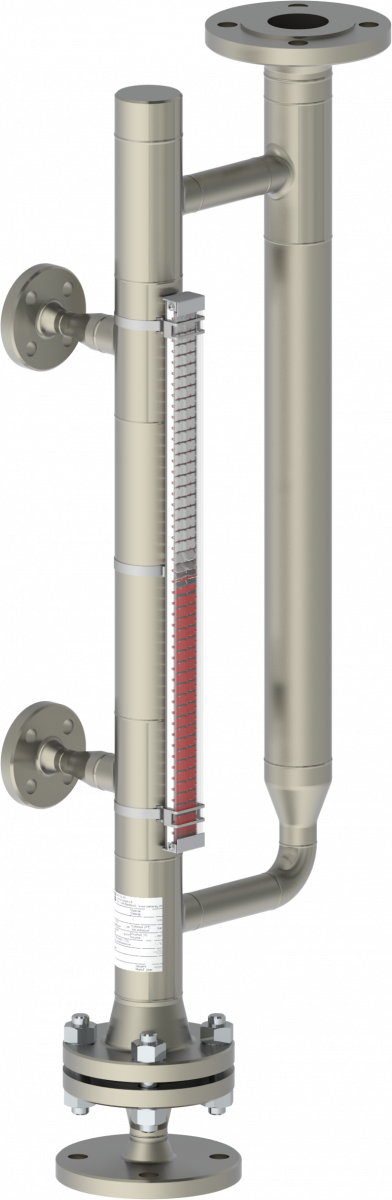

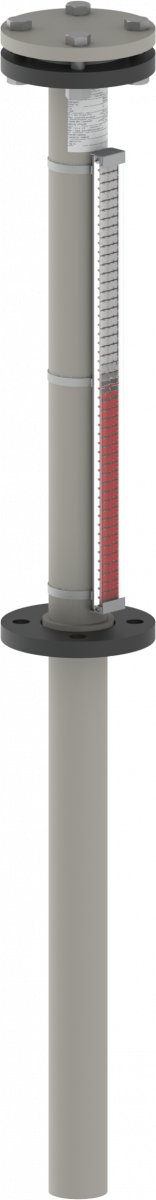

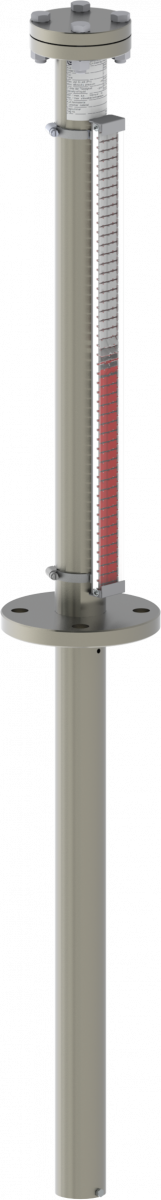

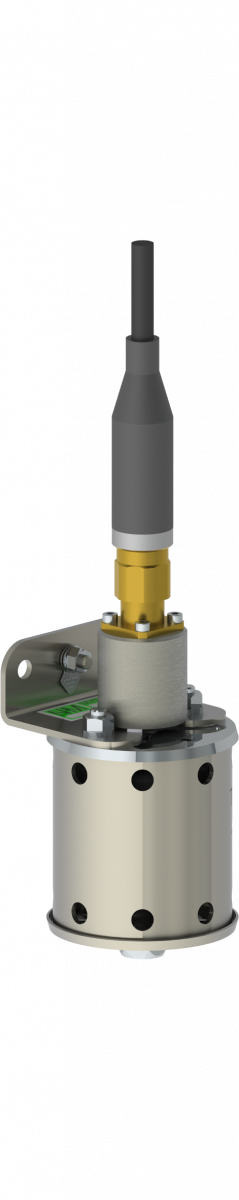

Instead of on the side of the tank, top of tank magnetic visual level indicators are installed on top of the tank.

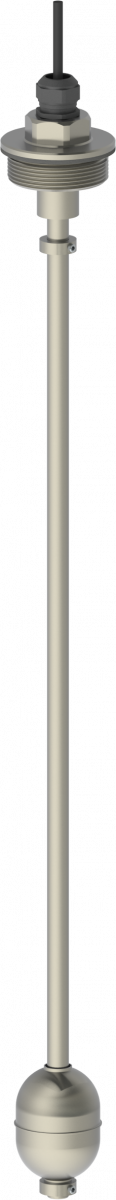

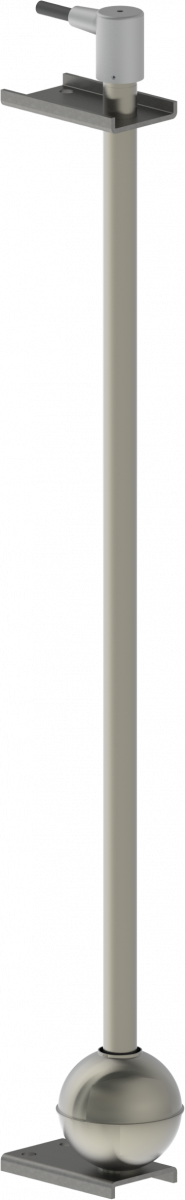

The magnet is not located in the float directly, but in a magnetic carrier found above the top of the tank that is connected to the float by a connecting pipe. The float system moves in a guide pipe and the fill level is displayed above the tank, as in the bypass visual level indicators. Thus, all the advantages of the magnetic visual level indicators are available.

Magnetic visual level indicators combine up to three functions in one device: level display, switch and transmitter. The display, which can be read across large distances, works without energy. The float records the fill level directly and inevitably and displays it without further calculations.

WEKA magnetic visual level indicators impress thanks to their compact design and their wide range of applications.

The WEKA function principle with a horizontal bar magnet ensures clear, operationally safe control of the gauge bar, the switches and the transducer. This is the case even with the biggest wall thicknesses of the float standpipe. Comparable to a compass needle, the float in the standpipe always aligns itself according to the patented rotating magnetic band integrated into the gauge bar. Large functional flexibility is combined with the advantages of the large field density of the bar magnet! Each gauge leaf has its own permanent magnet integrated. Thus, the gauge leaves are magnetically coupled and position-stabilised. Together with the insulating field of the rotating magnetic band, a clear level display is ensured even under difficult operating conditions (e.g. fast level change, vibrations). Select magnetic materials with the smallest degradation of the field strength ensure the preservation of the functional advantages of the WEKA bar magnet principle up into the highest operating temperatures. The low weight of the WEKA bar magnet principle allows a lightweight design of the floats and thus an extremely compact, material-sparing and contemporary design for the standpipe. Also ensured is the greatest possible radial clearance between the float and the standpipe – an advantage in the case of heavily soiled or high-viscosity fluids.

Like the bypass visual level indicators, top of tank visual level indicators offer a wide application range.

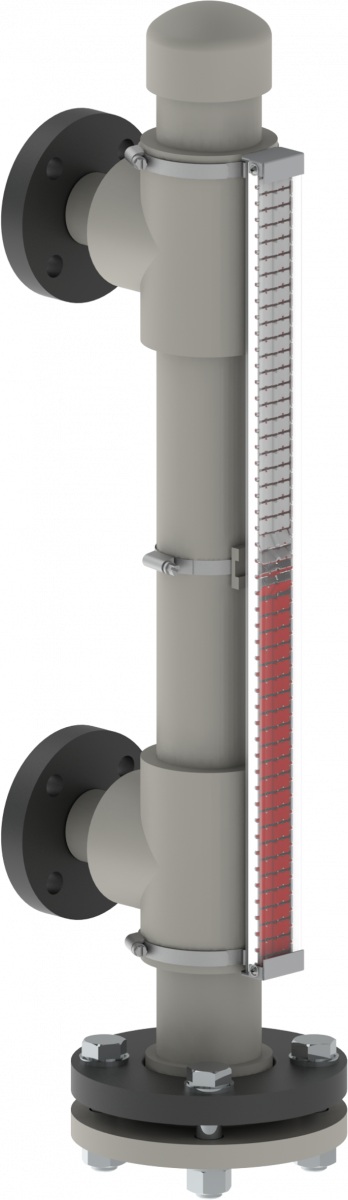

The material selection is also flexible.

- Standard materials: 316/316L 1.4435/1.4404, austenitic stainless steel of the A4 group

- Further possible austenitic stainless steels: 304/304L 1.4301/1.4306, 1.4571, 321, 1.4541

- Stainless steels with higher Mo content, such as: 1.4539 (904L; UNS N08904), 254 SMO (UNS 31254)

- Nickel alloys and special metals such as: Inconel/Incoloy/Hastelloy, titan alloys, zirconium, tantalum. Aluminium alloys

- Plastics: PVDF, PP, PE, PVC, ECTFE coating (Halar), PTFE-PFA lining, PFA coating.

- In principle, all possible non-magnetic materials are conceivable!

Energy-free, inevitable functioning

The WEKA magnetic visual level indicator is ideal when starting up systems. The displays works without energy and inevitably. Independent of control – and thus also in the event of a power cut – a visual level indicator is guaranteed on site.

Secure readability

The wide, red-silver colour-contrasted leaf indicator is easily and securely readable, even across large distances. The completely transparent leaf indicator in polycarbonate (PC) also ensures lateral readability. The not always unproblematic and also dangerous fluids are securely enclosed in the tight, pressure-resistant float standpipe and are separated from the indicator.

The secure readability of the level indicator is not impeded by turbidity or the translucence of the fluid to be measured.

Level measurement à la carte

As described, WEKA magnetic visual level indicators offer the ideal solution for nearly all operating conditions. For most applications you will find a suitable device from our standard range. However, special solutions are also repeatedly required for special operating conditions. Many versions are usable in dangerous areas according to ATEX or IECEx. Thus, many of our devices are also usable in potentially explosive environments.

Benefit from our many years of experience! Including the time-tested and patented WEKA magnet system for the float and the gauge bar, we have developed and constructed magnetic visual level indicators according to specific customer requirements for over 50 years. If needed, our standard interfaces to your control system can also be installed on these devices. The WEKA leaf indicator can be designed with a different colour contrast of the leaves. The WEKA magnet system with the gauge bar is also used to display stroke positions of hydraulic or pneumatic pistons and pressure accumulator membranes. For all of this, we offer you solutions on request for your special requirement.