Do you want to measure another fluid and need a new float? Do you want to connect a device with the level? Do you want to automate your system by evaluating the level in a control system?

Then you have come to the right place. Here you will find the suitable accessory or spare part.

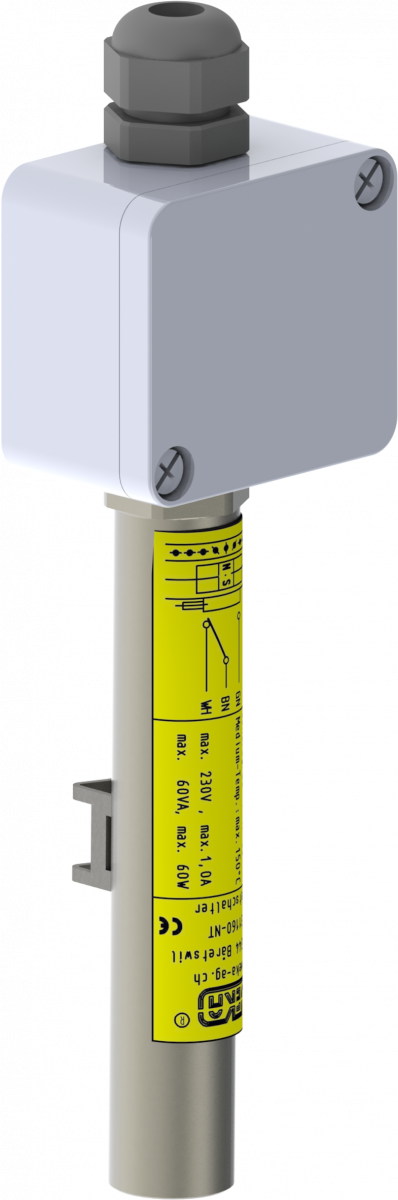

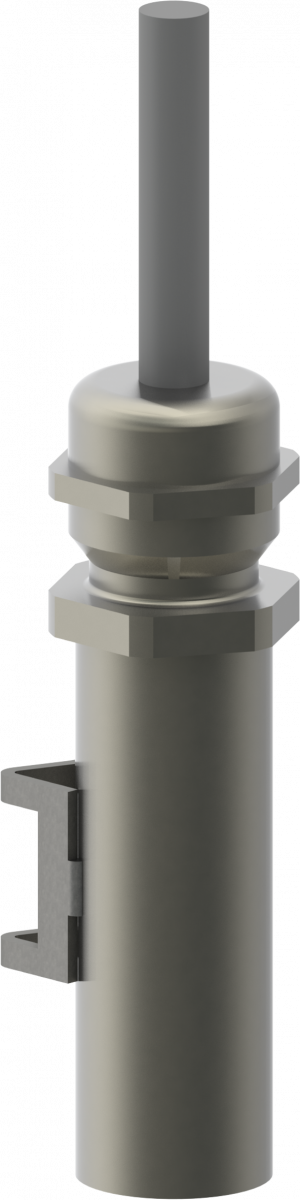

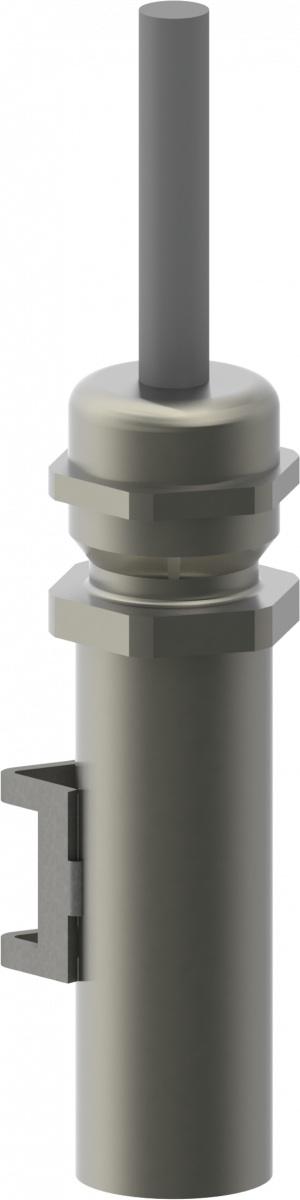

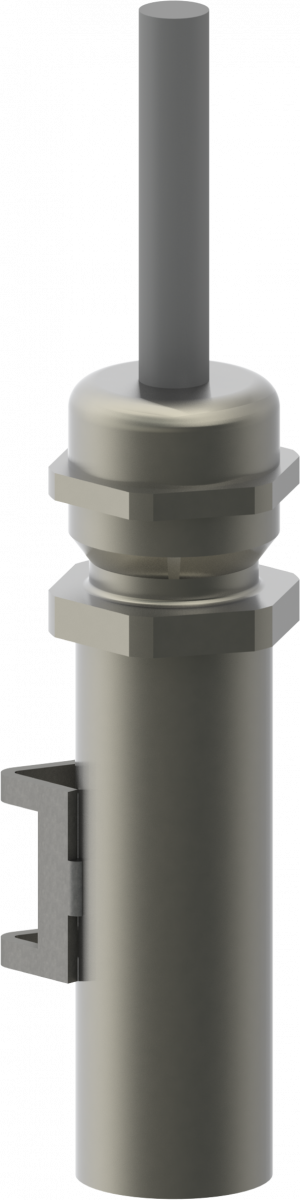

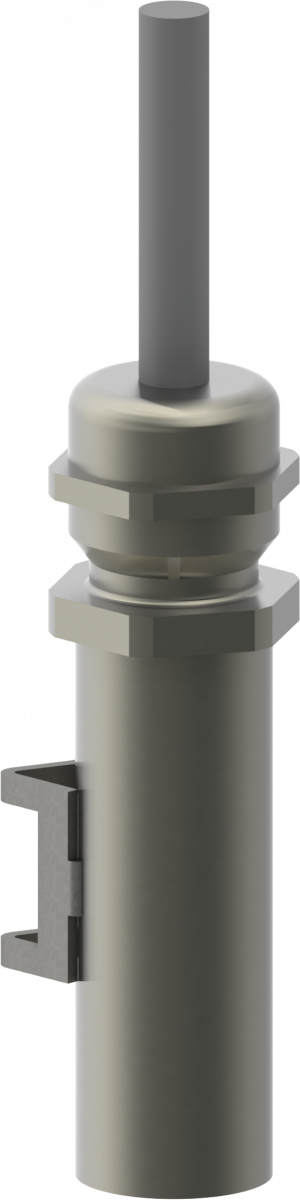

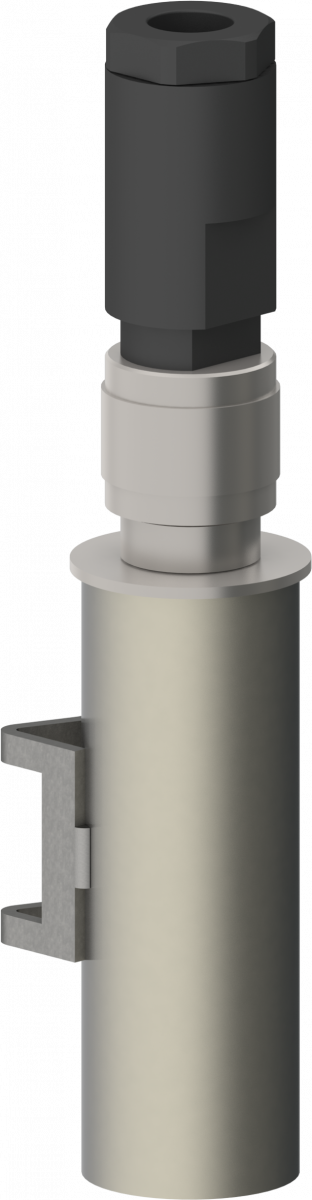

In addition to the float types, there are hundreds of accessory variants available for installation outside the float chamber