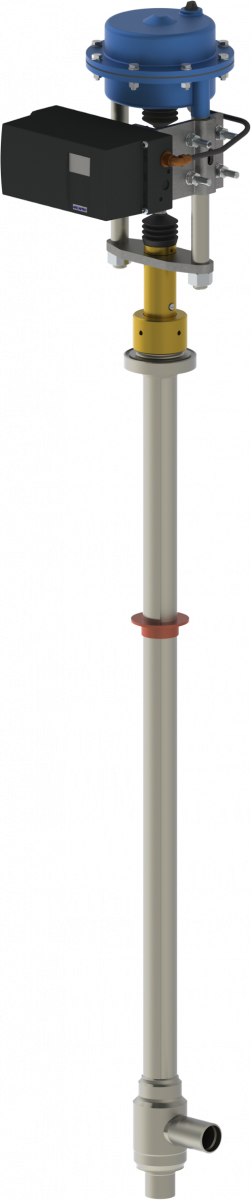

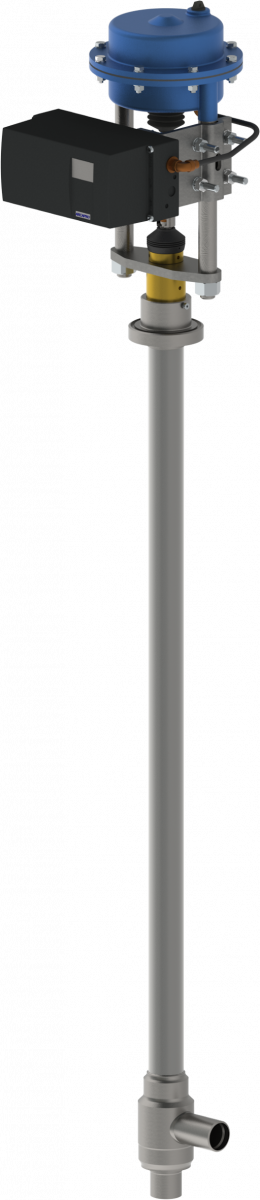

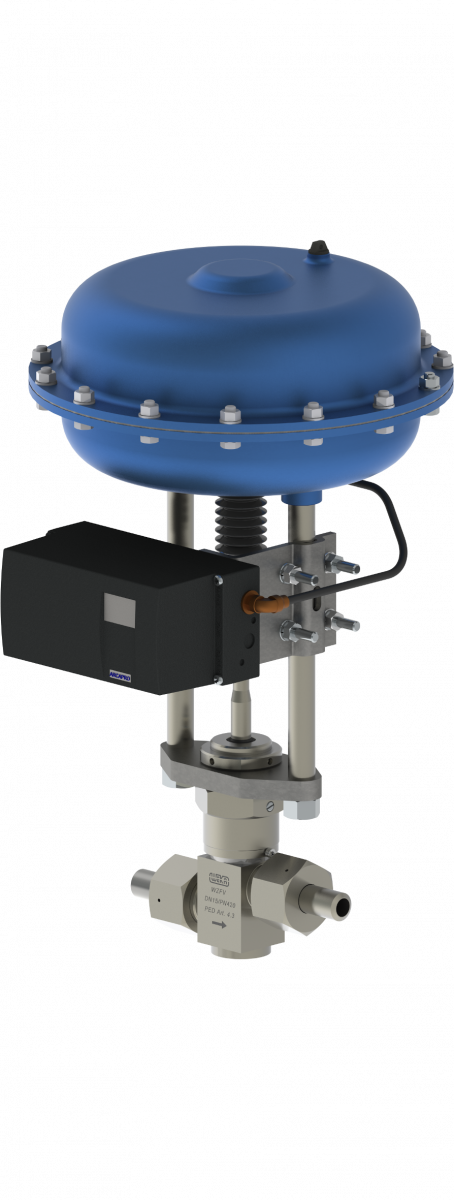

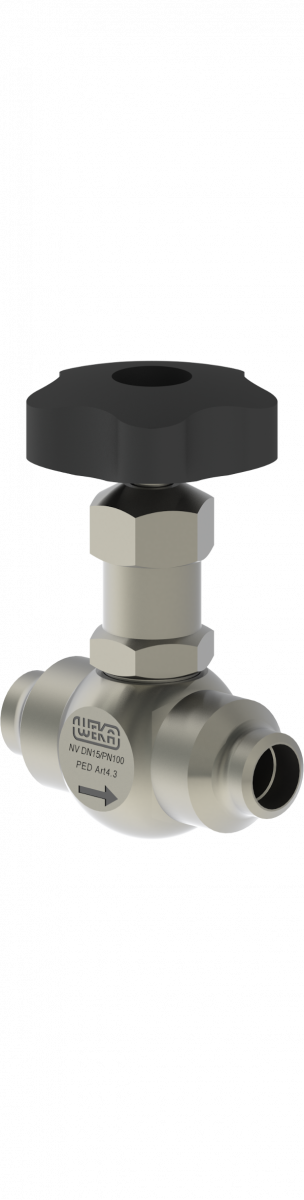

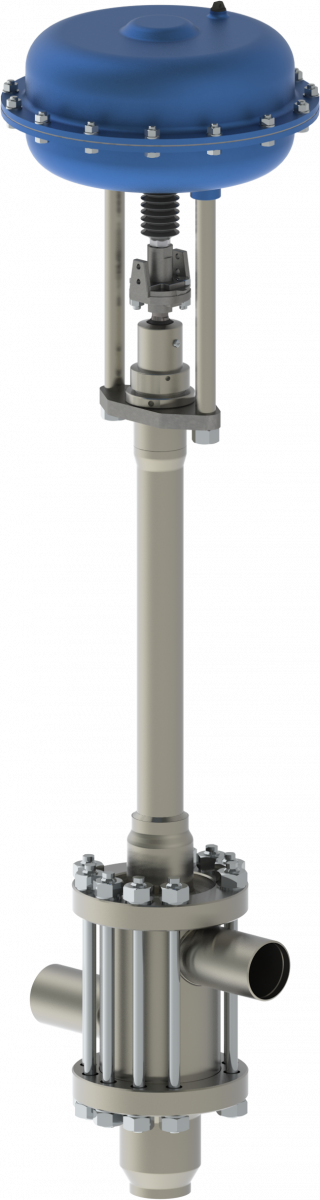

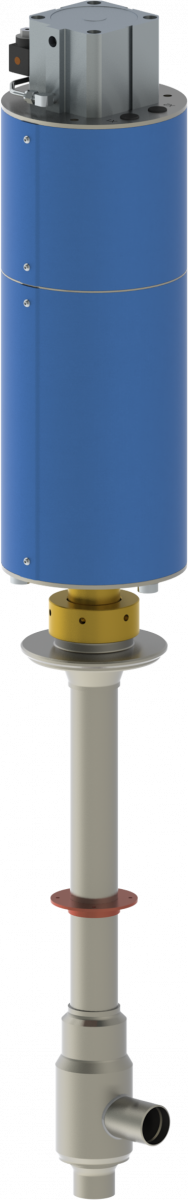

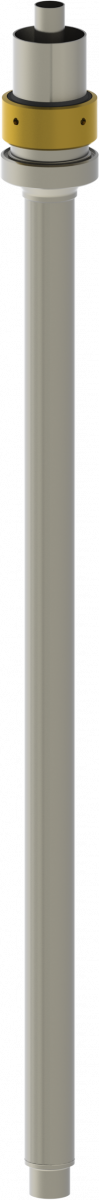

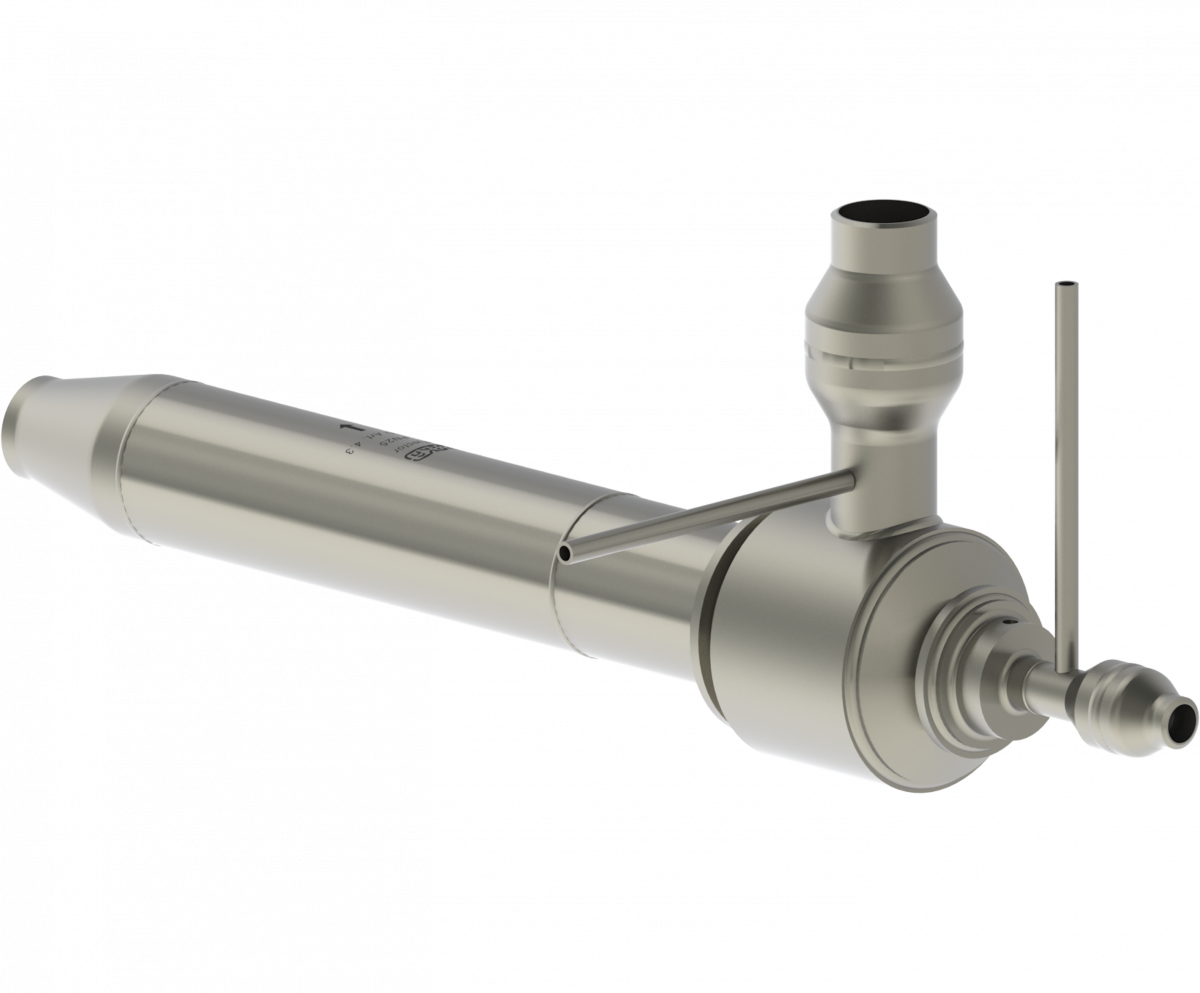

Since the 1970s, WEKA has offered a wide product portfolio for the regulation and control of fluids with temperatures close to absolute zero. The product range is used mainly in the liquefaction an refrigeration of helium and hydrogen but also extends to other fluids such as argon, neon, xenon as well as nitrogen and oxygen.

The product range is completed by high-pressure valves, ejectors and transfer line couplings.

At WEKA, particular focus is placed on the development of customer or use-specific solutions.