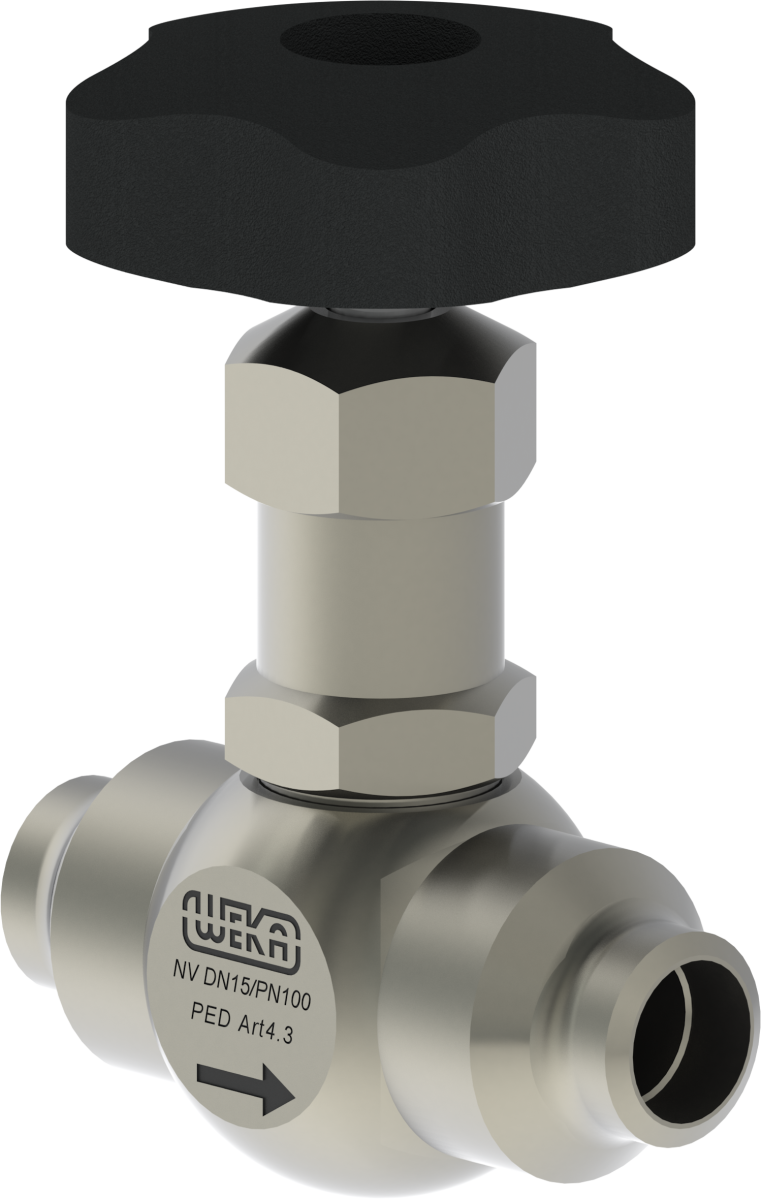

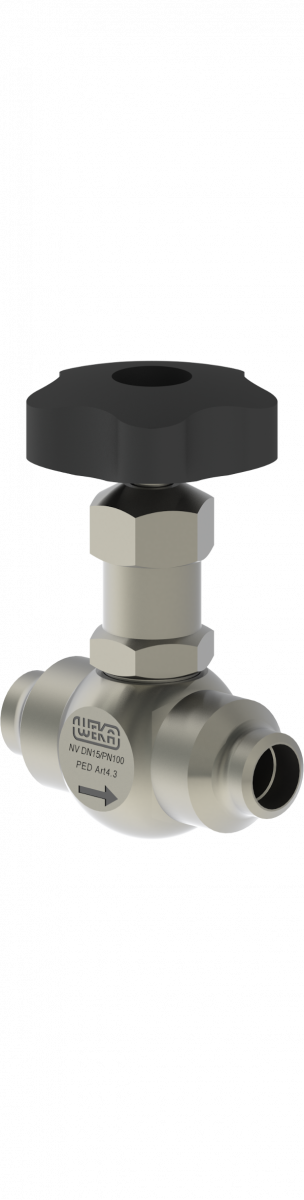

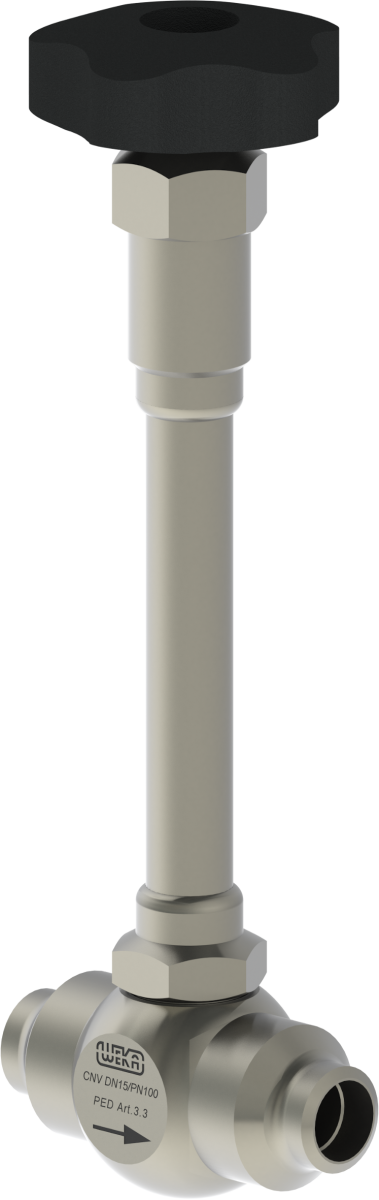

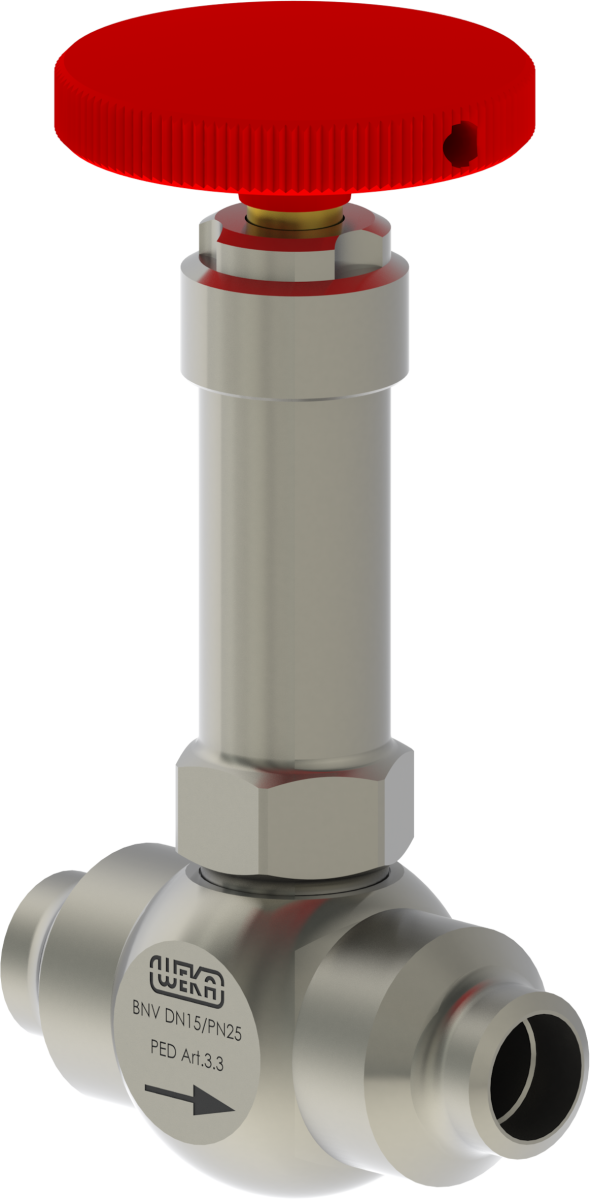

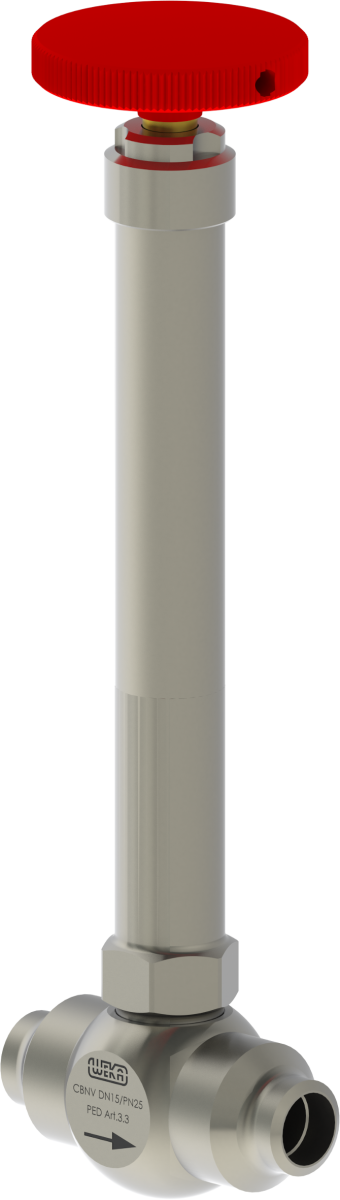

WEKA needle valves are used as process valves in a wide variety of applications, including in cryogenics. In the standard version, they cover the nominal width range DN4… DN15 and the pressure ratings PN110, PN260 and PN420. The seat seal has a metal design and the dynamic spindle seal is typically produced with a PTFE sleeve.

Needle valves

Download

Type of publication

Specific allocation

Type of publication

Specific allocation

Name

Download