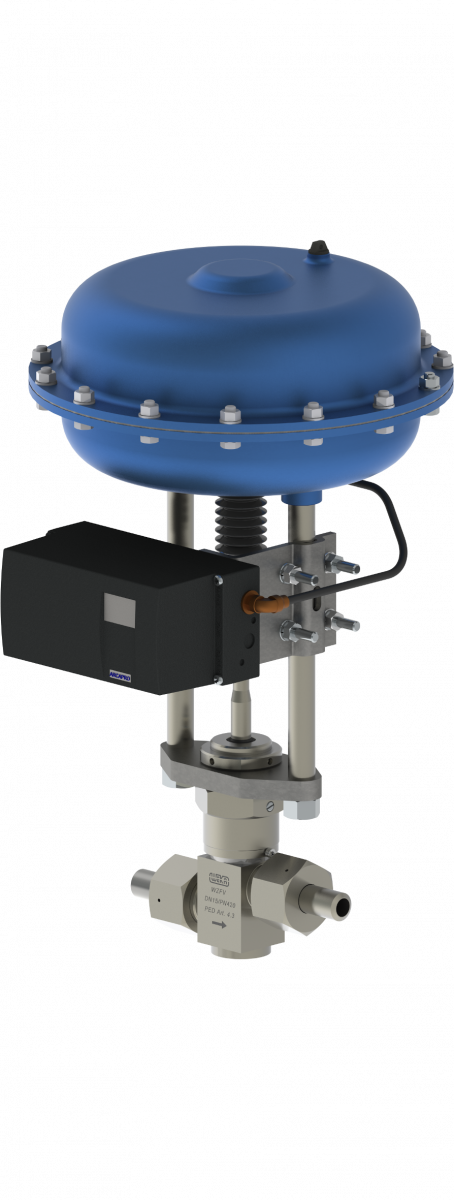

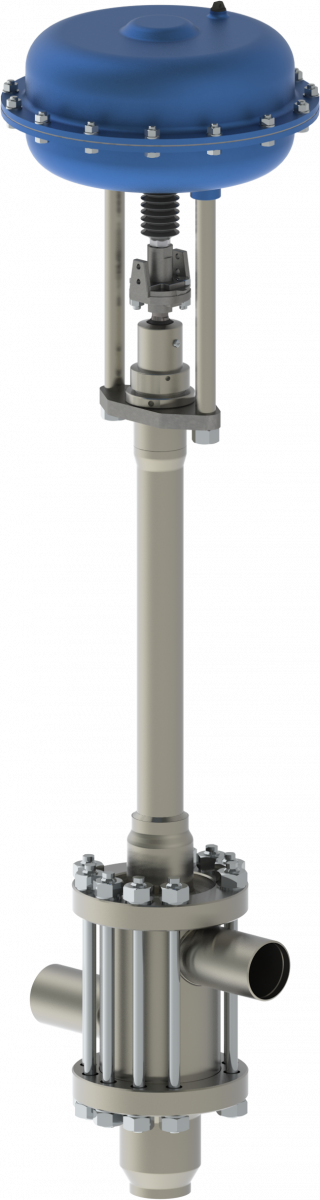

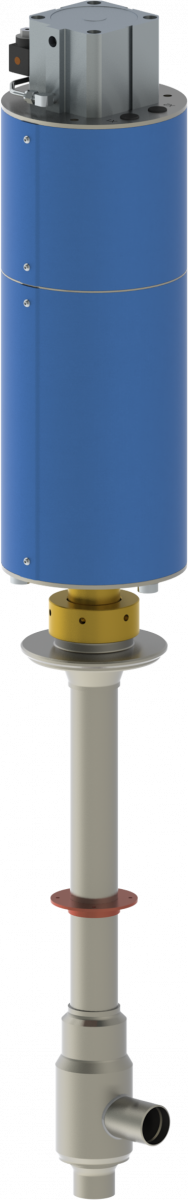

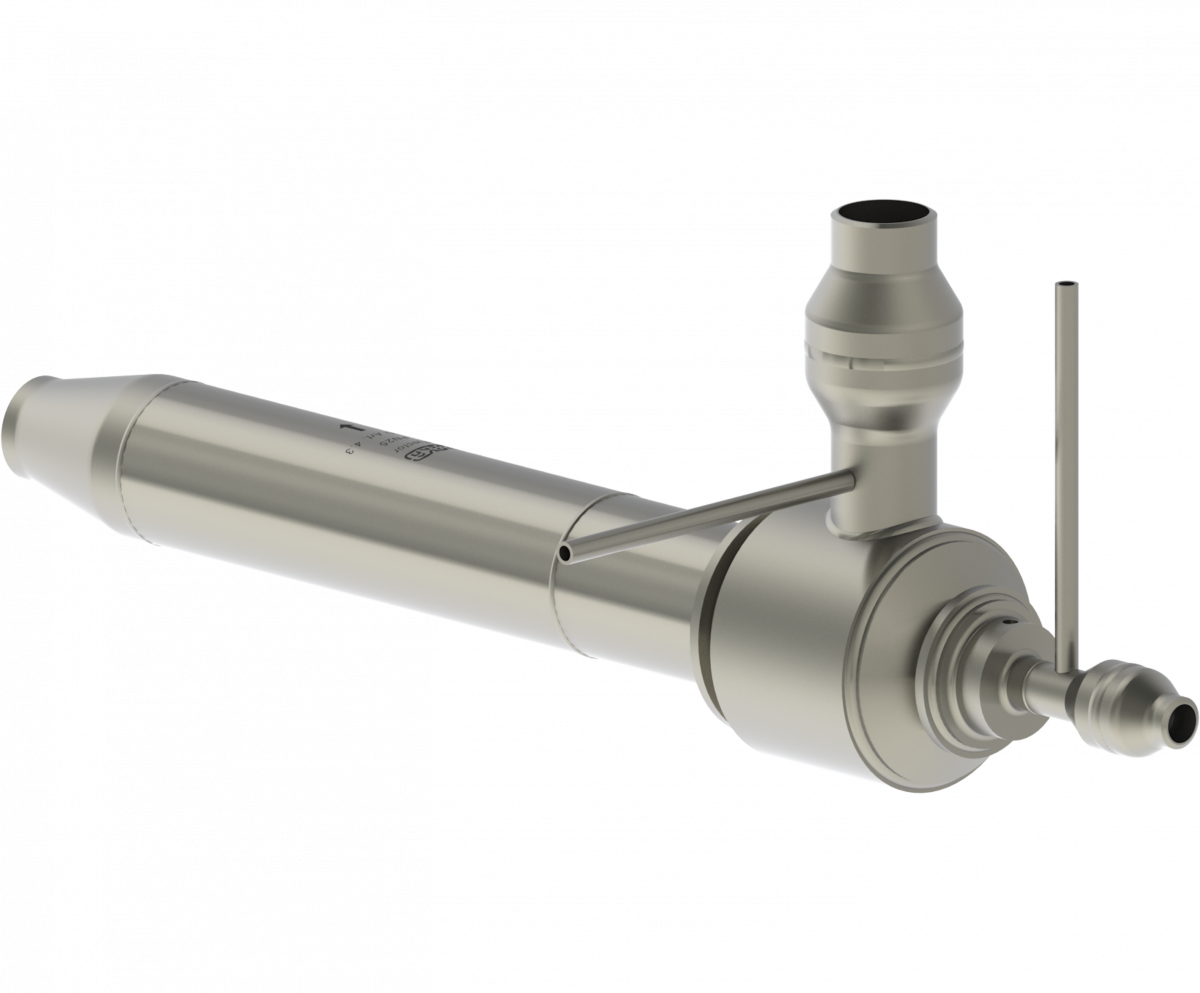

Along with turbines, compressors and heat exchangers, valves are among the key components of a condensing installation. Valves regulate the parameters and maintain the optimum operating point of a turbine and compressor. The accuracy of the control system and above all its constant stability thus have a significant influence on the efficiency of the plant.

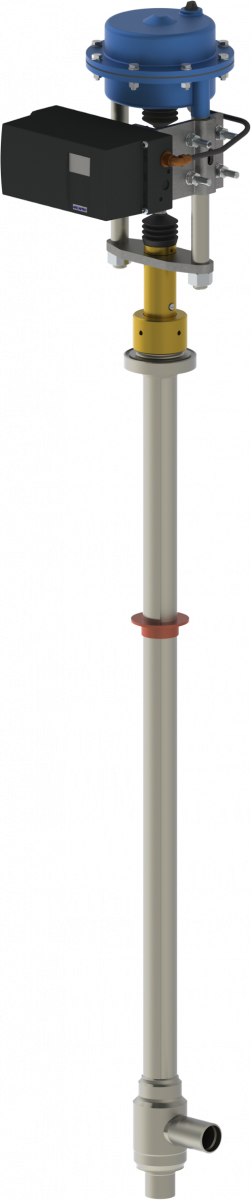

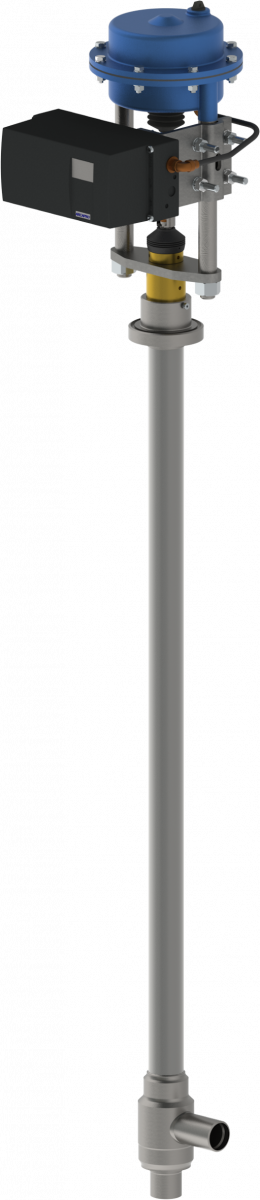

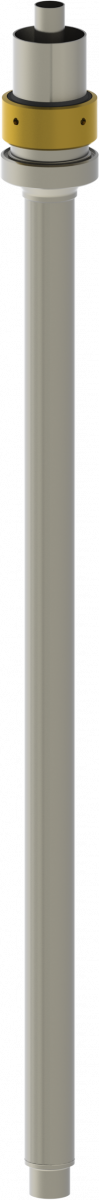

On the other hand, valves using thermally conductive materials connect the cryogenic lines with room temperature. This inevitable heat input in the system must be minimised to ensure the efficiency of a system. For this purpose, WEKA valves of the TEV and TEQV series use a design specifically developed for cryogenics, reducing the heat input and thus increasing the efficiency of the plant.